Product Introduction

Hook group is the most common load handling device in the crane machinery. Hook hangs on the wire rope of the lifting mechanism with the help of pulleys such parts. Hook is the most widely used among all the load handling devices. It has such characteristics as simple manufacture and strong usability.

Technical Description

- Hooks have single hook and double hooks according to the shape.

- Five strength grades M、P、S、T、V,are classified according to the mechanical property.

- Forging type hook and chip type hook are classified according to method of manufacturing.

- Hook often bears the impact of shock and cutting load in the working process,so hook material should have either enough strength or better toughness.

- Forging hook material adopts high-quality low carbon killed steel or low carbon alloy steel, such as 20 high-quality low carbon steel, 16Mn,20MnSi,36MnSi, which is annealed after being forged.

Product Advantages

- There are also two types for chip type hook:single hook and double hooks.

- Chip type hook is made up of hook chips which is punched and sheared from 16Mn steel plate of thickness no less than 20mm, and then riveted by rivets.

- When materials are unloaded, height direction of board hook and direction of steel plate rolling are the same, which can improve strength of hook.

- In order to make load uniformly distribute into every chip, and reduce abrasion of wire rope.

- Disconnectable base plates are set at the mouth of hook.

- Disconnectable base plates are set at the mouth of hook.

Safety Protection

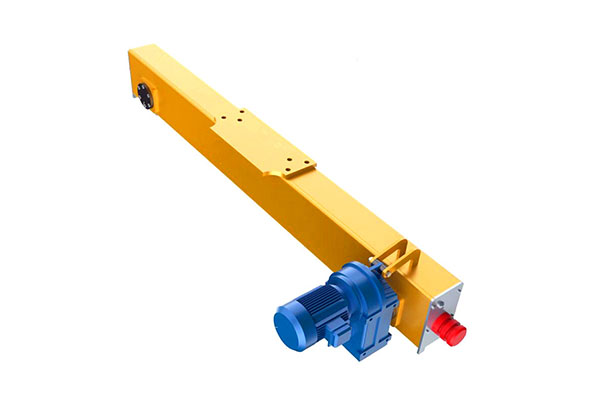

Lifting limit switch

Prevent the hook out of control when it has been lifted to the top position

Traveling limit switch

Stop the crane traveling smoothly when travel to the rail ends

Overload limiter

Prevent for the overload

Wire rope guide

Align the wire rope neatly on the reel to prevent the wire rope from messing and overlapping

We have the short circuit protection, emergency switch, interlock protection, overload protection, loss of voltage protection, grounding protection and voice-activated alarm lights and other safety protection devices

FAQ

- Q1:What object to lift ? applications and working environment ?

- Q2:Lifting capacity:__ton?

- Q3:Lifting height (H):__ m ?

- Q4:Span (S):__m ?

- Q5:Travel bay distance:__m ? do you need us offer rails and runway beams ?

- Q6:Control mode: pendant control, remote control or cabin control ?

- Q7:Power source: AC 3Phase __V / __Hz ?